WPC Composite Decking Versus Timber Decking

WPC composite is a modern alternative to wood due to it being virtually maintenance free as it does not require staining, is rot and splinter free and comes in a variety of colours as well as long manufacturers warranties.

Composite decking because it is solely made from reclaimed and recycled materials which were once destined for Landfill is an environmentally and sustainable option rather than destroying the forests of the future. It takes a minimum of 6 years to grow a Pine tree which is economical for deck board production.The traditional timber decking that we know so well unfortunately requires maintenance of cleaning off algae during the winter months, staining regularly in order to preserve the timber and only has a lifespan of 5-7 years dependent on the quality of the wood before the wood starts to show signs of serious wear.

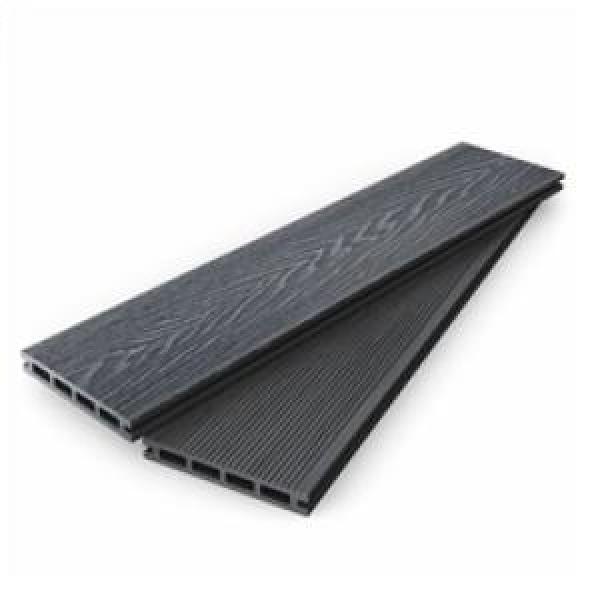

WPC composite is manufactured from reclaimed wood and recycled polymer based products, the manufacturing process of WPC composite is mixing approximately 50% wood flour made from reclaimed wood with 50% recycled polymer pellets, these 2 components are mixed together under temperature and the polymer adheres to the wood flakes thus encasing them in a protective layer, after cooling the composite mixture can be extruded under heat and pressure to form the composite boards and colours can be added.

WPC composite boards are offered in unlimited colours and also the latest technology in composite manufacture is now providing a co-extrusion process whereby a print or wood pattern can be applied to the composite board and then sealed with a polymer coating allowing for a realistic wooden appearance and this process by applying a further seal to the composite board further enhances its waterproof qualities and so now manufacturers are giving a 25 year warranty on this type of co-extruded product.

Whilst composite decking is 2-3 times the cost of a decent quality wooden alternative the lifespan can be in excess of 20 years with no degradation and virtually no maintenance apart from the odd clean. Whilst more expensive initially the durability can outweigh the cost and indeed enhance the value of a property and indeed be a selling tool if a homeowner is looking to sell rather than an inconvenience of a prospective purchaser who would have to remove that rotten decking thus creating a major snag for selling.

As production efficiencies are found the gap between the pricing will decrease making it more affordable and a viable alternative to wood deck boards.

English

English Japanese

Japanese Spanish

Spanish German

German Russian

Russian Arabic

Arabic Portuguese

Portuguese French

French Korean

Korean Thai

Thai